Water Treatment System STOPCOR

The advanced Corrosion & Limescale Control System that prevents plumbing and heating damage. Protect your home infrastructure with Stopcor softening and conditioning solutions.

- No electric power source required

- Zero carbon footprint

- It naturally generates current up to -1.5V

- No plumbing is involved

- Water treatment

- No water contact

- Suitable for drinking water

- Easy testing with a voltmeter

- Reduction of Limescale

- Corrosion control

- Efficiency of household appliances

- Easy maintenance with water

- 3 Years life time

- Environmentally friendly

- Non Toxic

- Easy maintenance with tap water

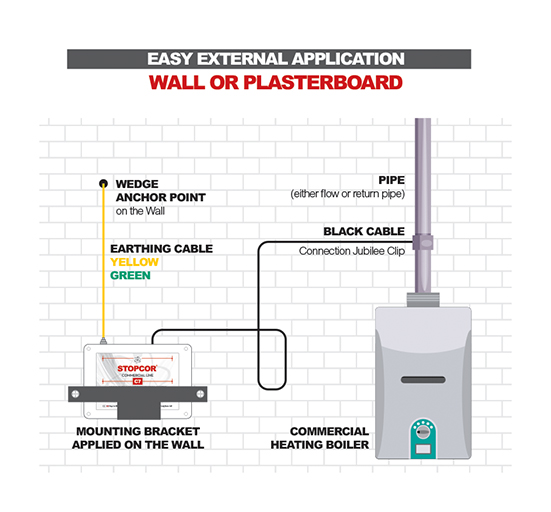

Our Commercial Line for Corrosion & Limescale Control

| PRODUCT LINE | Specification of KW & Sqft | Details |

| COMMERCIAL C5 | 80 KW - 500lt - 2000 Sqft | C5 Details |

| COMMERCIAL C7 | 100 KW - 1000lt - 3500 Sqft | C7 Details |

| COMMERCIAL C9 | 280 KW - 2000lt - 5000 Sqft | C9 Details |

- Self-contained device

- No external power source required

- No contact with water or liquids

- Reduction of limescale and sludge

- Consistent voltage and amperage

- 3 years of protection

- No intervention in the installations

- Environmentally friendly

- Easy testing with a voltmeter

- Large scale plumping installations

- Commercial heating boilers

- Commercial gas equipment

- Cylinders

- Water pipes

- Circulators

- Pumps

- Tanks

- Easy maintenance with tap water

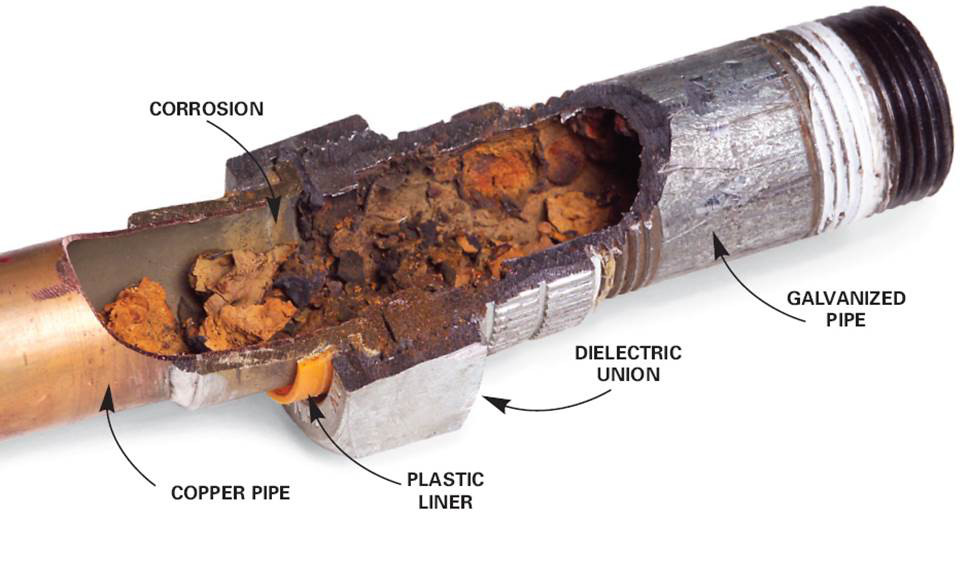

What Causes Electrochemical Corrosion?

Electrolysis is a naturally occurring phenomenon resulting in the corrosion of metal surfaces.

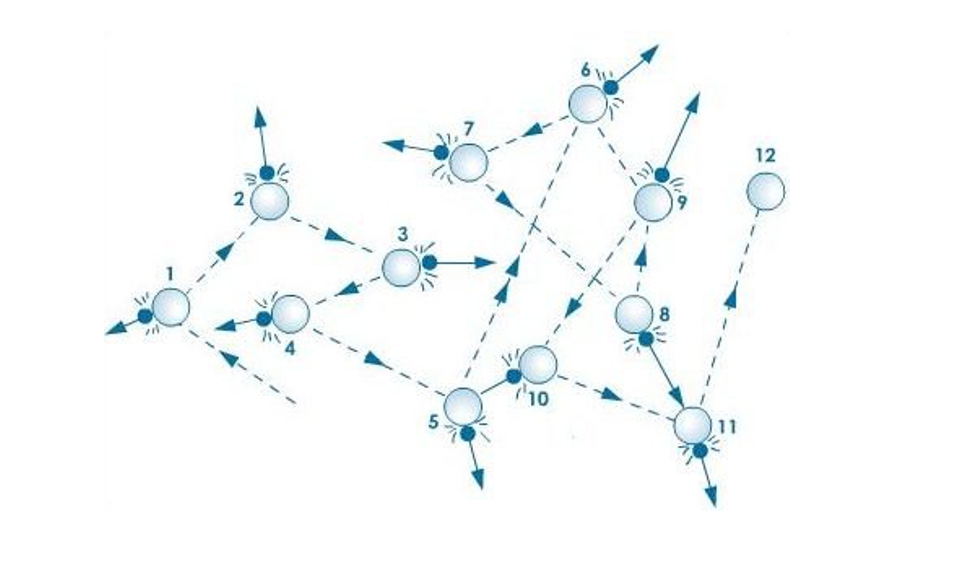

Electrochemical corrosion (electrolysis) is brought about by the flow of ions from negatively charged metals to positively charged metals when they are connected in the same environment. The resulting electromotive force appears as voltage. This voltage is proportional to the flow of the aforementioned ions and its increase directly affects the intensity of the electrolysis phenomenon.

The naturally occurring phenomenon of electrolysis manifests itself in metal structures, bridges, storage tanks and generally in plumbing installations, machinery, engines etc.

STOPCOR Reduces Limescale

STOPCOR uses a technology that has been successfully applied in both domestic and commercial setting for over 20 years.

In its formal state scale crystals form in complex structure and stick together.

STOPCOR imposes a direct current up to -1,5V without the need of an external power source that changes the crystal form of limescale to a simple structure.

It creates a magnetic field, thereby activating the Brownian movement in water which is the random movement of particles. Limescale loses its ability to stick and no longer forms deposits. It is simply washed away with water.

STOPCOR changes the balance of limescale and carbonic acid and thereby removing already existing deposits faster than they build up.

This way the piping network gets cleaned and the plumbing and heating equipment is protected by the damaging effects of limescale accumulation.

Moreover, the water treated by STOPCOR does not lose minerals, such as calcium and magnesium. The natural composition of the elements in the water remains the same. However, due to a change of the water surface tension, all plumbing parts such as taps and shower heads are scale free and the feeling on the skin is remarkably softer while taking a shower or even simply washing your hands.

STOPCOR Method. What is the Solution?

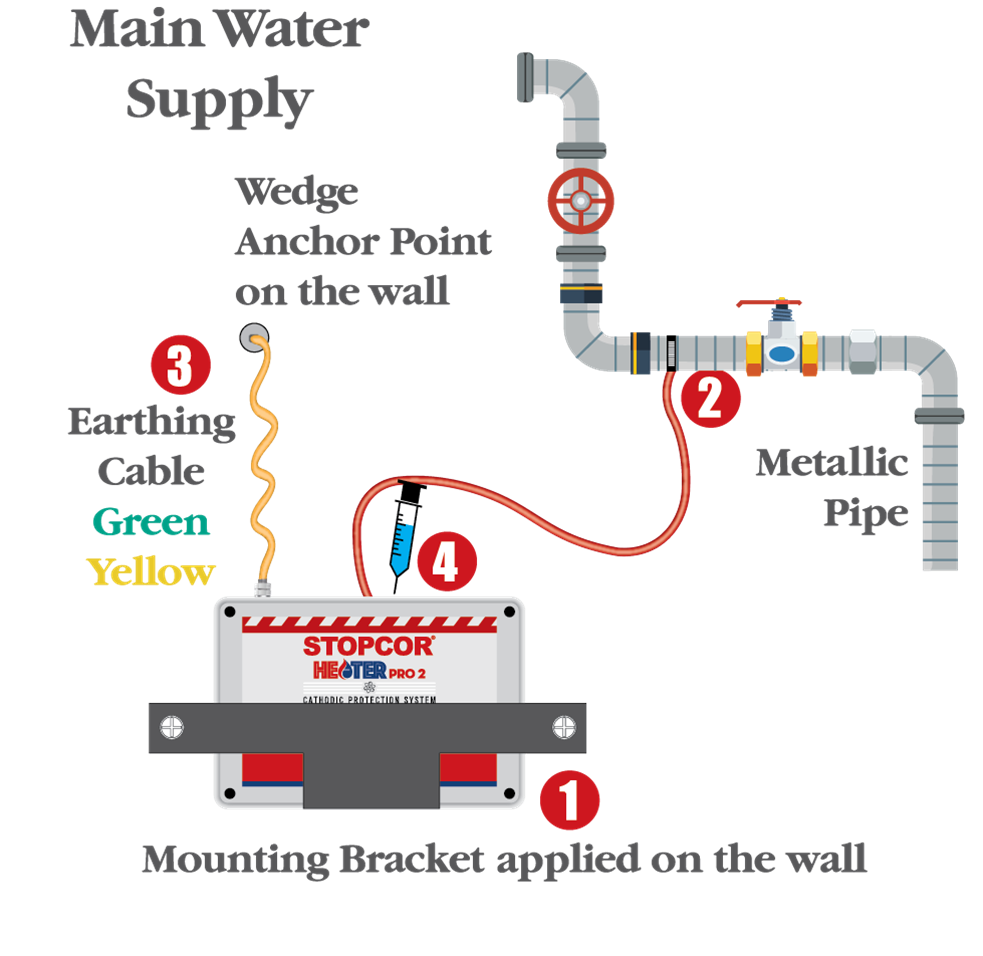

The proposed STOPCOR anti-corrosion method thereby provides cathodic protection through impressed current by the sacrificial anode in the self-contained device.

The impressed current covers and protects wide metal surfaces with much less sacrificed mass of active metal (anode).

The current is direct (DC) and compatible with other metals since it is naturally generated.

The negative charging of the protected metals is completely satisfactory, resulting in the surface which used to be anode of galvanic element (i.e. negative oxidizing pole) becoming cathode of electrolytic cell (i.e. negative reducing pole).

The protected surface remains negatively charged but its action is reversed and is now inclined to undergo reduction instead of oxidation.

The impressed current must be over 0,8 volt, but it must not exceed 10mA.

There are several advantages of this device compared to other methods. Here are some of them:

- The device is totally self-contained and does not require an external power source to function.

- It does not require monitoring, maintenance or repair because when the anode mass is exhausted, it simply stops being effective and is discarded.

- It does not pollute the environment.

- It is completely safe.

- It is not affected by weather conditions or any other circumstances.

- It does not come into contact with liquids and if connected to any water supply it does not come into direct contact with drinking water.

- It provides consistent voltage and amperage throughout its lifespan.

- It provides long term protection.

- It is affordable due to low manufacturing costs.

- Fitting it does not require any technical skills whatsoever.

- Any modification, intervention or alteration in the installations where the device is fitted in unnecessary.

- Its cathodic protection is completely compatible with other metals since magnesium is a very active metal whose naturally generated voltage is imposed on all of the other metals.

- It protects extended surfaces compared to other methods available.

It has been observed that several installations present specific challenges as a result of their technical specifications, the nature of the materials inside the pipelines or the composition of the soil in their location. Given these conditions STOPCOR Heater PRO 1&2 and STOPCOR Commercial line are the ideal solution!

Using this particular method the anodes are capable of providing current density of up to 100 mA per device, thereby increasing the amperage of the impressed current and providing protection of metal surfaces on a much wider scale. Moreover, the protective action is powerful even in cases of metal surfaces coming in contact with acid fluids.

Depending on the composition of the soil, installations in some areas have been known to absorb part of the impressed current of anodes. As a result, the voltage of the impressed current current falls below 1 volt.

In order to increase the impressed current to the appropriate levels we rearrange the configuration of the device sequentially, thereby achieving the desired effect.

As for metal constructions surrounded by water, (i.e. ships) the grounding rod must be immersed in the water. This is achieved by a bar of copper underneath the ship. Although constantly immersed in the water, it is insulated so that there is no conducting contact with the ship’s hull. This bar is the grounding surface of the ship on which all the electrical grounding is attached. Finally, constructions equipped with a closed cooling circuit, (i.e. vehicle engines) grounding is achieved by an electrode component which is fitted on a point of the circuit constantly run by water. This electrode comes with en external pin which is connected to the cathodic protection device on the upper side using a clamping bolt.

This pin goes through the electrode and is inserted in the material while being insulated so, as to keep it fixed and ensure the sealing of the closed circuit.

The metal used in the pin is either titanium or niobium in order to avoid oxidation.

Installation Examples